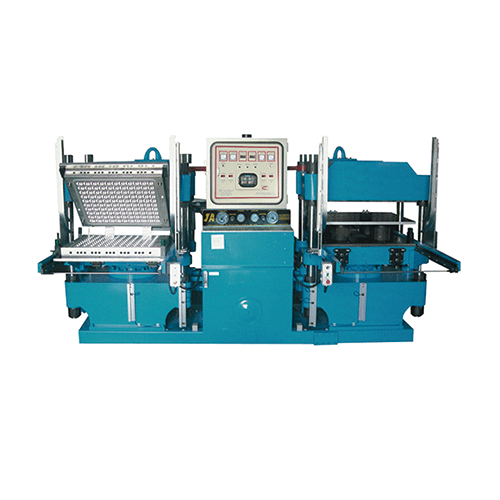

Transfer Compression Molding Machine - FCSR Series

Categories : Compression Molding Machines

APPLICATIONS: Small rubber silicon products, rubber capacitor, golf ball.

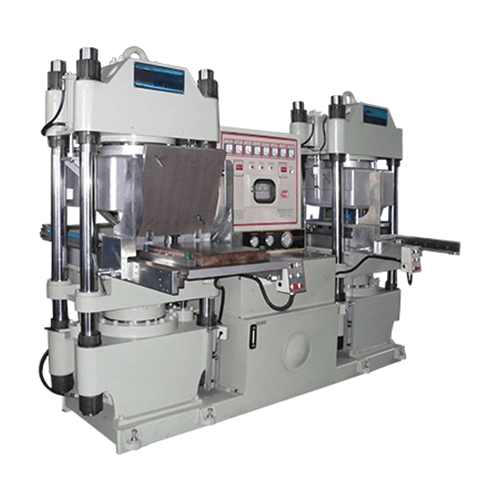

2RT Mold-Open Rubber/Silicone Compression Molding Machine / HCC_D2

Categories : Compression Molding Machines

Features This type of machine is multi-functional, because it is suitable to be used for top opening double or triple molds. High force adopts Dual powers and each oil system is designed respectively. It is steady, quiet and low frequency of malfunctions. Two shafts can be operated simultaneous.

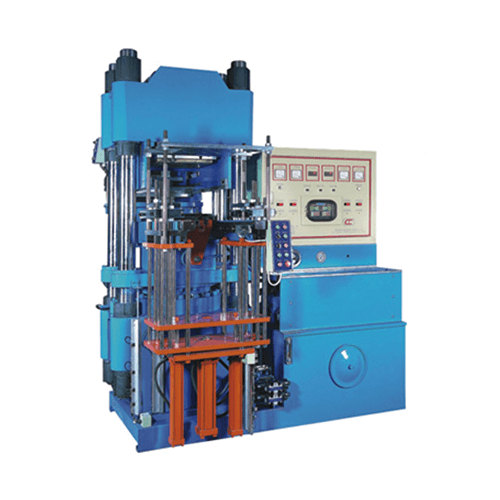

4 Stations 2RT Mold-Open Rubber/Silicone Vacuum Compression Molding Machine /VCC-F2

Categories : Compression Molding Machines

Features This type of machine is multi-functional, because it is suitable to be used for top opening double or triple molds. Dual powers and individual oil system are adopted. Each oil system is designed respectively. It is steady, quiet and low frequency of malfunctions. Two shafts can be operated simultaneous.

Sphere Rubber/Silicone Compression Molding Machine

Categories : Compression Molding Machines

Equip with patent rail mold-open, very fast and easy to operate. The complete set includes both molds and molding machine. Big working bench, plenty cavities, high yield. Nature rubber Rubber of metal bonded parts Oil-resistance rubber NBR+PVC concoction Synthetic rubber Medical/Pharmaceutical usage rubber Heat resistance rubber

3RT Mold-Open + Air-Jig Rubber/Silicone Vacuum Compression Molding Machine / VCC-D3J

Categories : Compression Molding Machines

Features The 4RT surpasses the traditional top opening mold that can be used for taking out the final product when there are triple or four molds with the design of opening mold, pushing out the mold in between, loading the bottom mold, lowering the mold in between, and rising thimble to hit the final production.

Patent Rail Mold-Open Rubber/silicone Compression Vacuum Molding Machine VCC-DP

Categories : Compression Molding Machines

Nature rubber Rubber of metal boned parts Oil resistance rubber NBR+PVC concoction Synthetic rubber Medical/Pharmaceutical usage rubber Heat resistance rubber.

Patent Rail Mold-Open Rubber/Silicone Compression Molding Machine / HCC-DP

Categories : Compression Molding Machines

Features This type of machine is suitable to be used for double molds. It is capable of speedy productivity. For the rail mold opening, the opening angle is up to 90 degrees. It is very convenient for operation. High force adopts Dual powers and each oil system is designed respectiv

3RT Mold-Open Rubber/Silicon Continuous Transfer Injection Molding Machine-TCC-S3

Categories : Compression Molding Machines

●Nature rubber ●Rubber of metal boned parts ●Oil resistance rubber ●NBR+PVC concoction ●Synthetic rubber ●Medical/Pharmaceutical usage rubber ●Heat resistance rubber

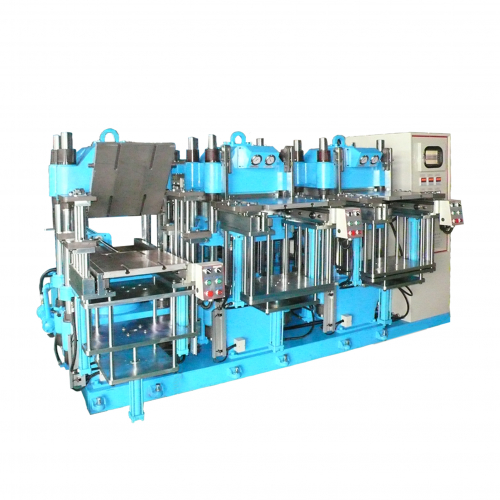

3 Stations 3RT Mold-Open Rubber/Silicone Compression Molding Machine /HCC-T3

Categories : Compression Molding Machines

Features This type of machine is multi-functional, because it is suitable to be used for top opening triple or four molds. Hydraulic system Designed by proportional pressure and flow ratio, which is steady, quiet and low frequency of malfunction. Two shafts can be operated simultaneously. Slow speed of mold calibration is provided to make the calibration safer and more accurate. Molds can be precisely positioned. A 100% safety design for positioning is available to prevent molds from damage. The speed to open/close the mold is adjustable. It is very accurate and reliable.